Mitigate Procurement Risks and Optimize Costs

Businesses in 100+ industries and sectors rely on the SpendEdge platform to derive deep insights, ensure supply chain predictability, and reduce costs

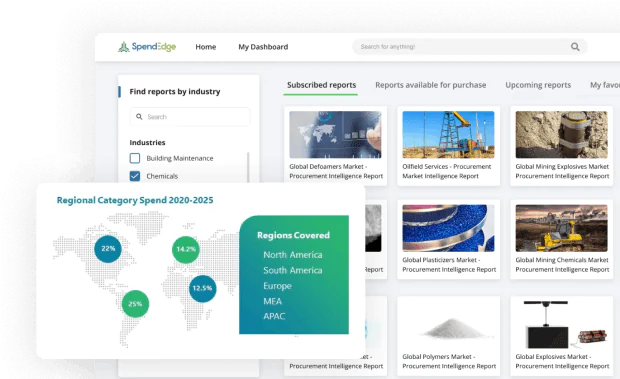

Start your trial today SpendEdge Procurement Market Intelligence Space