Effective food and beverage supply chain management plays a critical role in optimizing procurement processes and ensuring operational efficiency. Transparency within the food and beverage supply chain presents significant challenges due to the vast network of products, suppliers, regulations, and processes involved. With food processing plants, logistics companies, and various stakeholders contributing to this intricate web, maintaining end-to-end visibility remains a complex task. Ensuring seamless traceability and implementing supply chain risk management strategies are essential to sustaining smooth operations and mitigating disruptions. As industry continues to evolve, strengthening food and beverage supply chain practices becomes imperative for improved efficiency, compliance, and overall business resilience.

Where does the problem occur for the F&B Industry?

At the heart of this challenge lies the need to track the origin, quality, and safety of each ingredient and component, amidst the intricate interplay of suppliers at different tiers. The sheer diversity and volume of inputs, coupled with stringent food safety requirements and regulatory frameworks, further compound the complexity.

Embracing transparent supply chain strategies is paramount, not merely as a regulatory obligation but to mitigate risks and fortify consumer trust. By illuminating every node of the food supply chain, manufacturers can proactively identify potential vulnerabilities, ensuring that each component adheres to requisite standards of food safety and quality.

Moreover, transparency empowers manufacturers to anticipate and meet evolving food trends and consumer demands, thereby fostering agility and resilience in the face of fluctuating food demand. It also serves as a catalyst for promoting ethical practices, from sustainable sourcing to responsible production methods, thereby aligning with the values and expectations of conscientious consumers.

In addition to regulatory compliance, transparency in the food supply chain confers strategic advantages, enabling companies to optimize logistics, reduce food miles and food prints, and mitigate the risk of food shortages through informed decision-making and proactive risk management. Ultimately, it is through transparency that the food industry can uphold its commitment to delivering safe, high-quality food products while building enduring trust with consumers.

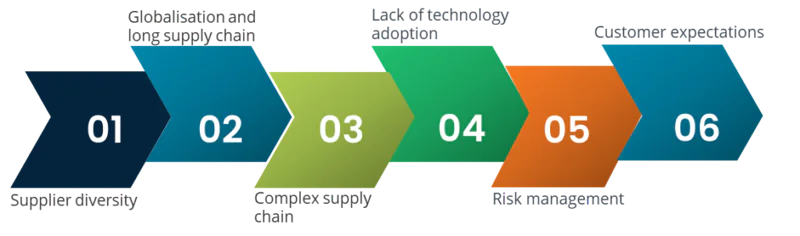

Challenges in Food and Beverage Supply Chain Management Procurement Process

Supplier Diversity: Food and beverage companies often source ingredients from a diverse range of suppliers, each with its own production methods, quality control measures, and levels of technological sophistication. This diversity can make it difficult to standardize transparency practices across the supply chain.

Globalization and Long Supply Chains: Many ingredients used in the food industry are sourced internationally. Different countries have varying regulations, standards, and practices related to food safety, labeling, and sourcing. Ensuring transparency across borders requires navigating these differences.

Complex Supply Chains: The food value chain is often quite complex, involving multiple stages such as farming, processing, packaging, transportation, and distribution. Each of these stages involves various actors, adding to the complexity of traceability efforts.

Lack of Technology Adoption: Some suppliers, especially smaller ones, might lack the technological infrastructure to provide real-time data about their processes. This can hinder efforts to track and monitor products effectively.

Risk Management: Transparency is crucial for identifying and managing potential disruptions, such as shortages of raw materials, geopolitical issues, or transportation challenges. Without a clear view of the supply chain, it becomes challenging to respond quickly and effectively to mitigate such risks.

Consumer Expectations: Consumers are increasingly concerned about the provenance and quality of the food they consume. Meeting these expectations requires companies to provide detailed information about the products’ journey from farm to fork.

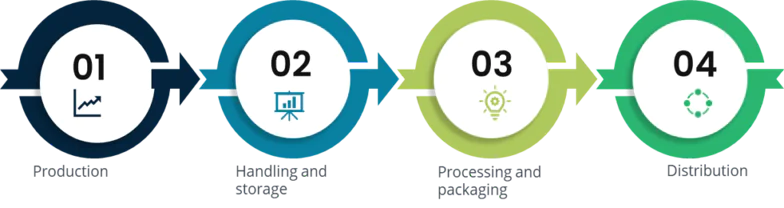

Stages of Supply Chain Management in Food Industry

Production

The food supply chain starts at the production level, which is where the food supply chain starts. Food products are developed or grown in compliance with national and international regulations. To guarantee the food’s safety, quality, and appearance, laws and regulations are put in place.

Handling and Storage

The products go through the required procedures after they are harvested. Some potatoes, for instance, need to be washed before being packed for shipping, while others can just be thrown in a bag and shipped. As an alternative, some goods are sent to facilities that prepare food so they can be made into chips or crisps. The food supply and its intended use determine the precise handling technique.

Processing and Packaging

Before food goods are permitted to proceed on to the packaging stage, they must meet stringent food safety regulations. Once they fulfil the requirements, they are suitably packaged and prepared for the next stages of the food supply chain.

Distribution

The food products are sent from the packing plant to their final destinations once they have been packed and prepared. These destinations typically involve markets, but food can also be transported to other areas of the food business. Some food goods are transported by air, but the majority are shipped. The term “food mile” refers to the distance that separates the producer from the consumer and is used to quantify the environmental effect of food production.

6 models of Food Supply Chains that can be chosen by Businesses

While the innovation for the Food and Beverage industry is ever evolving, there are a few models that one can choose from. Here are the various models:

1. Continuous Flow Model

Within high-demand production environments, this particular model stands out for its ability to provide stability in inventory and raw material management. It proves particularly advantageous for well-established brands with mature supply chains, especially when the customer profile is expected to remain constant.

2. Fast Chain Model

Embraced by the fast food industry, the Dynamic Trend Model epitomizes agility in catering to swiftly changing consumer tastes. As culinary preferences evolve akin to fashion trends, restaurants pivot promptly by revamping menus with inventive offerings. Leveraging a nimble supply chain, they procure fresh ingredients and concoct novel recipes, ensuring they seize the fleeting moments of trendiness. This proactive approach allows eateries to unveil and market captivating culinary innovations before trends dissipate, thereby perpetuating their relevance in the ever-dynamic gastronomic landscape.

3. Efficient Chain Model

This is beneficial for businesses operating in highly competitive environments. It emphasizes high efficiency in delivery logistics to maintain a competitive advantage. This model prioritizes effective inventory management and maximizing productivity from production equipment and labour. In industries with tight competition and thin profit margins, businesses recognize the importance of reducing costs throughout the supply chain while ensuring product availability for vendors. By adopting the efficient chain model, companies can optimize their operations and enhance profitability in competitive markets.

4. Agile Model

Within the realm of food supply chains, the Agile Paradigm encompasses a quartet of fundamental tenets: virtual integration, process harmonization, network centrality, and market acumen. Virtual integration facilitates real-time monitoring of fluctuating consumer demands, enabling responsive adjustments in product offerings. Process harmonization entails a collaborative ethos pervading supply chain functions, fostering seamless coordination among stakeholders. Network centrality underscores the egalitarian participation of all supply chain actors. Lastly, market acumen empowers swift recalibration of production volumes in tandem with shifts in consumer preferences.

5. Custom-Configured Model

The Tailored Configurations Model seamlessly merges the agility of the Agile Paradigm with the fluidity of continuous flow models to accommodate diverse product permutations in the food supply chain. Suited for contexts where consumer personalization reigns supreme, this model epitomizes adaptability to evolving tastes and preferences, ensuring sustained consumer satisfaction.

6. Flexible Model

Empowering food enterprises to navigate the crests and troughs of demand fluctuations, the Flexibility Framework encompasses three pivotal facets: part segmentation, precision stocking algorithms, and adaptive planning. By diversifying supplier networks and embracing automation, the supply chain stands primed to respond dynamically to demand oscillations while optimizing inventory levels and operational efficiency.

Contact us now to solve your procurement problems!

Conclusion

The intricate tapestry of the food supply chain necessitates robust supply chain strategies to navigate the complexities inherent in ensuring food safety and transparency. From the farms to the tables, a myriad of stakeholders, including logistics companies and food processing plants, play pivotal roles in orchestrating the seamless flow of food products. However, challenges such as food shortages, evolving food trends, and stringent food safety requirements underscore the imperative for agile and adaptable supply chain models. By embracing innovative approaches like the Fast Chain Model and Agile Paradigm, businesses can proactively respond to shifting food demand and consumer preferences, thereby fostering resilience in the ever-evolving food industry landscape. Moreover, the specter of globalization and long supply chains necessitates diligent efforts to mitigate risks and optimize food miles and food prints. Through collaborative efforts and technological advancements, stakeholders can enhance transparency and traceability across the food trade, thereby fortifying consumer trust and ensuring the delivery of safe, high-quality food products. By leveraging strategic supply chain management in food industry, companies can navigate the intricacies of the food industry landscape while upholding the highest standards of food safety and integrity.