By: Ankur Rishi

Key Takeaways:

- The chemical industry is undergoing a digital revolution, leveraging AI-driven research, smart manufacturing, and data analytics to optimize processes and accelerate product development.

- Challenges during digital transformation include employee resistance, system integration, data security, costs, skill gaps, supplier adoption, compliance, vendor choice, and risk management, which require careful planning to overcome.

- Digital technology trends such as IoT sensors and blockchain are reshaping chemical supply chain operations, enhancing transparency, traceability, and efficiency.

- Businesses in the chemical industry must focus on visibility, efficiency, resilience, and sustainability. Collaboration and strategic planning are essential to navigate economic challenges and maintain competitiveness.

- Margin pressure, supply chain resilience, business network management, and sustainability considerations are significant challenges faced by sourcing teams in the chemical industry.

- SpendEdge offers solutions for identifying suppliers, managing risks, benchmarking deals, and navigating upcoming trends in the chemical industry to drive efficiency and growth.

The chemical industry is currently undergoing a digital revolution, marked by innovations such as AI-driven research, smart manufacturing, and data analytics. These advancements are optimizing processes, enhancing sustainability, and accelerating product development. Chemical companies are embracing business digitalization, which involves integrating technology to transform interactions with consumers and stakeholders across departments, services, and channels.

A genuine digital transformation process requires a thorough examination, questioning, and reconfiguration of business processes tailored to the firm, its clients, and its suppliers. However, challenges arise during digitization, including employee resistance, system integration, data security, costs, skill gaps, supplier adoption, compliance, vendor choice, and risk management. Overcoming these obstacles requires careful planning to realize the advantages of digital procurement.

Digital technology trends are reshaping chemical supply chain operations by facilitating real-time tracking, data analytics, and automation. IoT sensors monitor inventory levels to ensure efficient stock management, while blockchain enhances transparency and traceability, thereby bolstering safety and compliance. These digital trends present various opportunities to develop new industrial chemical solutions.

In summary, digital tools optimize logistics, minimize risks, and boost efficiency in the chemical supply chain, fostering growth and innovation in the industry.

Chemical industry: Outlook

Considering the delayed market growth, businesses must focus on the future need for visibility, efficiency, resilience, and sustainability. By 2024, supply chain planning and management will no longer be limited to logistics departments but will become a part of the strategy discussed at company board levels. The chemical industry is expected to face economic challenges due to inflation, interest rates, regulations, and other factors. However, businesses involved in chemicals and their supply-chain partners can counter these effects by collaborating on solutions that increase efficiency. The C-Suite should continue to prioritize the focus on supply chains to make sure that these efficiencies are not used as a way to commoditize supply chains and lower costs in the short term, but rather to super-charge them with deep capability to unlock businesses’ competitiveness. Therefore, creating optionality in the supply chains and ensuring resiliency under the current market situation will be a strong way to maintain the flow of supply chains and related growth.

Challenges faced by sourcing teams in the chemical industry

Margin pressure and supply chain resilience:

A major issue faced by chemical companies is the need to maintain their profit margins. This challenge is primarily caused by the emergence of new competitors, a scarcity of specific raw materials, substantial investments in chemical plants, and strict government regulations. The decisions made by management regarding cost-cutting measures, Return on Investment (ROI), and growth are likely to have a significant impact on the procurement department of these companies. Procuring raw materials in large quantities like oil, gas, and coal from commodity markets is difficult for chemical companies due to volatile prices that can harm financial performance and planning.

Needs and benefits of business networks:

Chemical companies are dealing with over 50,000 suppliers who provide raw materials, services, and infrastructure. To manage these suppliers effectively, companies negotiate, review, and classify them, taking into account the technical aspects of supplier integration. This poses a challenge for the teams as they need to integrate with one or more business networks to connect with suppliers using standardized interfaces for process efficiency. Because of the existence of multiple competing business networks, companies must evaluate their requirements and benefits before choosing the most suitable one.

Sustainability considerations:

For procurement teams in the chemical industry, sustainability has become a major concern. All chemical companies are required to comply with sustainable regulations, given their resource-intensive nature. Procurement managers are faced with a growing number of government sustainability regulations and market pressure from downstream customers demanding sustainable operations and products. In addition to this, finding suppliers who follow sustainability standards and offer competitive pricing is the biggest challenge. Companies must look for those using recycled packaging materials and sustainable processes for chemical production.

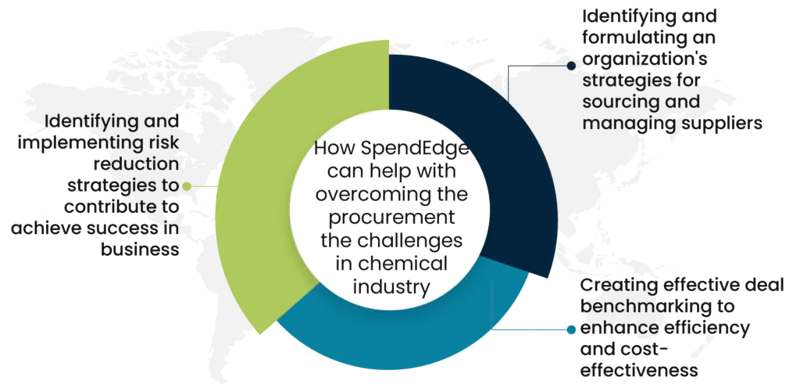

How SpendEdge can help with overcoming the procurement the challenges in chemical industry

Identifying and formulating an organization’s strategies for sourcing and managing suppliers:

Our approach to evaluating suppliers goes beyond traditional measures like revenue and performance, we look for vendors who can provide the most value to your business. It’s important to keep track of your suppliers to avoid any potential issues that could harm your business. Our team of experts uses statistical analysis and modeling techniques, along with exhaustive data sets, to accurately predict potential risks and assign risk scores based on probability and severity. This allows us to provide actionable insights to help you prevent supplier risks and other threats. Our supplier intelligence solutions will enable you to build up your diverse pipeline and onboard certified vendors.

Identifying and implementing risk reduction strategies to contribute to achieving success in business

Our team can help you identify and manage risks associated with your supply chain, and prepare for potential disruptions, geopolitical issues, and compliance risks through the implementation of countermeasures and contingency plans to reduce financial risks such as chemical market fluctuations. Our early warning system can alert you to impending risks, allowing you to resolve them quickly and save costs. We can also help you avoid penalties and legal consequences by identifying new regulatory compliance risks associated with hazardous chemicals in advance. With our risk mitigation plan, you can assure stakeholders of your commitment to managing risks and boost their confidence.

Creating effective deal benchmarking to enhance efficiency and cost-effectiveness

Businesses can analyze potential contracts and partnerships by comparing them to competitors on various parameters, including pricing, discounts, and SLAs. This type of deal benchmarking involves examining strategies and technologies used by industry leaders and competitors. Through this analysis, CPOs and supply chain managers can make informed decisions based on research. Identifying needs and requirements, industry standards, and the best suppliers and vendors to partner with are some of the benefits of deal benchmarking. It enables companies to prepare comprehensive strategies and make informed decisions.

What will be upcoming trends for chemicals in 2024?

Regional dynamics:

The competitive landscape in the chemical industry has undergone significant changes in the past three years, forcing companies to rethink their long-term strategies. Energy market fluctuations, evolving regional policies, and supply chain disruptions have sparked concerns about Europe’s deindustrialization. To adapt to these challenges, some chemical companies have started to re-examine their assets and supply chains. As technology evolves and decarbonization efforts increase, additional changes in talent requirements and clean electricity availability are expected to emerge. Chemical companies are expected to continue adjusting their portfolios in 2024 as they make strategic decisions about their future in this new environment.

Focus on digital and artificial intelligence:

Digital and artificial intelligence (AI) technologies are important to the future of many industries, but in the chemical industry, data is becoming an important feedstock for innovation and operational excellence. The chemical industry has been digitalizing its operations for decades, but it is only recently that digitalization has accelerated to a point where companies should be digital to help retain a competitive advantage. Companies seem to be moving past the stage of addressing specific use cases in silos and moving toward a broad approach to digitalization that integrates systems across operations and businesses. With digital integration, companies are benefitting from increased productivity, accelerated innovation, improved decision-making, and stronger customer relations.

Stronger commitment to sustainability:

2024 will see environment regulations get more stringent. According to the International Energy Agency (IEA), the chemical sector is still “the largest industrial energy consumer and the third largest industry subsector in terms of direct CO2 emissions”. The agency goes on addressing the issue of sustainability within the chemical industry stating that “to get on track, government and industry efforts need to address CO2 emissions from chemical production, as well those generated during the use and disposal of chemical products.” On top of accelerating their reduction of harmful waste, businesses involved in the chemical industry will need to agree to tangible initiatives to change their sustainability footprint, and doing so while building sustainable, transparent, and traceable value chains. The new “European Commission Decisions” on the management and treatment of waste gas in the chemical sector as well as the EU Chemicals Strategy for Sustainability will see businesses gearing up to comply with these legal norms, adopted to reduce their environmental impact, commit to being sustainable, decoupling from fossil fuel dependencies, phase out polluting products, and seriously adopt circular economy practices. Where emission reductions are in place for production, scope 3 emissions in the supply chain come into focus.

Businesses will strive to create optionality:

To cope with the current market situation, businesses will focus on creating optionality. This means they will adapt their existing supply chain models to take advantage of all possible growth opportunities and expand their market share. By doing so, they will be better prepared for a recovery when times become more favourable. Industry players will continue to seek smarter ways to partner and become more resilient in order to stay in their market and improve their profitability. This may involve switching suppliers, pivoting from export.

The success story of how SpendEdge helped one of its clients with procurement

The chemical industry is going through a digital transformation that will bring about changes in various areas such as research and development, product compliance, procurement, and sales and marketing. However, it is important to consider the potential effects of this transformation on the operations and the challenges that will be faced during this transformation.

A market player in the chemical industry based in the US that operates around the world and procures chemicals for drug manufacturing has limited visibility into the supply chain, leading to inefficiencies and unexpected disruptions. The client was also facing challenges related to compliance and risk management.

Our procurement specialists analyzed historical data and market trends, which helped the client select better suppliers and improved supplier negotiations. Our insights also helped the client enhance traceability in the supply chain and assigned risk scores to help in making appropriate supply chain decisions, ensuring compliance with regulatory requirements.

Our assessments and solutions increased the efficiency of procurement operations, enhanced supply chain visibility to detect disruptions timely, and reduced the impact of disruptions.

Contact us now to solve your procurement problems!

Conclusion

The chemical industry is amidst a significant digital transformation, where advancements like AI-driven research and smart manufacturing are revolutionizing operations. Chemical companies are embracing business digitalization to enhance sustainability and accelerate product development. However, this shift presents challenges such as employee resistance and data security concerns. Overcoming these obstacles requires strategic planning and adoption of digital procurement strategies.Looking ahead, the industry anticipates market growth despite economic challenges, driven by factors like clean energy transmission and evolving energy transition sectors. To navigate these changes successfully, businesses must prioritize chemical excellence and sustainability. Trends like the adoption of digital and artificial intelligence, coupled with a stronger commitment to clean energy and sustainability, will shape the industry landscape in 2024. This includes a focus on creating optionality within supply chains and addressing challenges related to margin pressure, supply chain resilience, and sustainability considerations.SpendEdge overcome procurement challenges by implementing strategies for supplier management, risk reduction, and deal benchmarking, businesses can enhance their procurement operations and ensure supply chain resilience. Through such initiatives, the chemical industry can drive innovation, foster sustainable growth, and address emerging market demands effectively.

Author’s Details

Ankur Rishi

Vice President, Sourcing and Procurement Intelligence

With more than 12 years of advisory experience, Ankur manages platform content and services within the sourcing and procurement vertical. Over the years, Ankur has provided consulting services to category leaders from chemicals, energy, and packaging industry, on varied topics, such as category strategy, spend analysis, commodity pricing, and clean-sheet analysis.