By: Manpreet Kaur

Mid-sized businesses are companies that are larger than small businesses yet smaller than large enterprises, in terms of revenue, workforce, and size. Although the definition may vary by industry and region, mid-sized businesses generally have more resources than small businesses while still maintaining some degree of flexibility and adaptability. These businesses play an important role in the economy, contributing to both job creation and innovation. Unified procurement involves a centralized and streamlined approach to acquiring goods and services across an organization. In other words, it means consolidating purchasing processes to improve efficiency, reduce costs, and ensure consistency.

Unified procurement benefits mid-sized businesses by centralizing purchasing processes, reducing costs, and improving supply chain efficiency. It streamlines supplier relationships, negotiates bulk deals, and ensures consistent quality across the organization. This approach enhances visibility into spending, allowing for better strategic decision-making. Ultimately, unified procurement enables mid-sized businesses to optimize their supply chains, reduce redundancies, and achieve economies of scale, contributing to overall operational effectiveness and competitiveness.

How can mid-sized businesses integrate and optimize their procurement and supply chain processes to achieve a competitive edge?

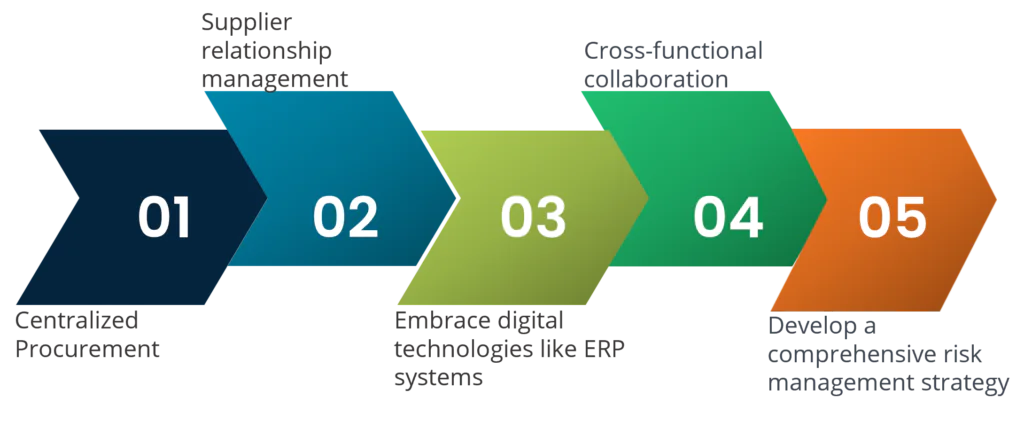

Centralized Procurement:

Introduce a centralized procurement system to unify purchasing activities across the organization. This strategic move facilitates improved negotiation capabilities with suppliers, minimizing duplication of efforts and enhancing overall procurement efficiency. By consolidating procurement functions, the system ensures a cohesive approach, fostering synergy among various departments. This not only streamlines the acquisition process but also enables more effective cost management and resource allocation. The centralized system empowers the organization to leverage its collective buying power, resulting in better deals and terms from suppliers. Overall, implementing this consolidated approach optimizes procurement, promoting resource efficiency and bolstering the organization’s strategic and financial positions.

Supplier Relationship Management (SRM):

Cultivate robust partnerships with crucial suppliers, fostering collaboration to gain a comprehensive understanding of their supply chains. Engage in cooperative contingency planning to develop resilient strategies together. This proactive approach facilitates rapid resource access in times of disruptions, ensuring a more agile response to unforeseen challenges. By establishing strong relationships and open communication channels with key suppliers, organizations can enhance their adaptability, mitigate risks, and strengthen their overall supply chain resilience. This collaborative effort not only secures the availability of essential resources but also fosters a sense of shared responsibility, creating a foundation for long-term stability in the face of dynamic market conditions.

Embrace digital technologies like ERP systems:

Adopt digital solutions such as Enterprise Resource Planning (ERP) systems, e-procurement tools, and supply chain management software to revolutionize business operations. These technologies offer instantaneous visibility into processes, fostering transparent and streamlined communication with both suppliers and customers. By integrating ERP systems, organizations can enhance efficiency, automate tasks, and optimize resource utilization. E-procurement tools facilitate seamless procurement processes, while supply chain management software ensures real-time tracking and responsiveness. Embracing these digital advancements not only improves operational effectiveness but also positions businesses to adapt swiftly to market changes, resulting in enhanced collaboration, data-driven decision-making, and overall competitiveness in the evolving business landscape.

Cross-functional collaboration:

Promote interdepartmental collaboration, fostering synergy between procurement, logistics, and finance teams. By encouraging cross-functional cooperation, organizations establish agile frameworks capable of swiftly adapting to evolving market dynamics and supply chain disruptions. Integrated efforts enable cohesive decision-making, enhancing the collective response to challenges. This collaborative approach not only improves communication and coordination but also ensures a comprehensive understanding of business operations. Through shared insights and expertise, cross-functional teams can proactively address issues, optimize resource allocation, and drive innovative solutions. Ultimately, this collaborative synergy positions the organization to navigate uncertainties with agility, resilience, and a unified strategic vision.

Develop a comprehensive risk management strategy:

Formulate an all-encompassing risk management strategy by identifying potential threats to the supply chain and devising robust mitigation plans. This involves diversifying suppliers, establishing backup sources, and implementing contingency plans to preemptively address uncertainties. The strategy ensures a proactive stance in mitigating disruptions by systematically evaluating and preparing for potential risks. By fostering supplier diversity and creating alternative channels, organizations fortify their resilience against unforeseen challenges, reducing dependency on single sources. This comprehensive risk management approach optimizes preparedness, allowing for agile responses to fluctuations and safeguarding the continuity of operations in the face of various supply chain uncertainties.

Diversify your supplier base to reduce risk:

Mitigate risk by diversifying your supplier base, introducing multiple sources for critical components or materials. This strategic approach provides a safety net, offering alternatives in the event of disruptions. By cultivating relationships with various suppliers, organizations enhance their resilience and decrease vulnerability to dependencies on single sources. Diversification not only minimizes the impact of potential disruptions but also fosters competition among suppliers, potentially improving overall efficiency and cost-effectiveness. This proactive strategy bolsters supply chain stability, ensuring adaptability in dynamic market conditions and safeguarding against the consequences of unexpected events that may impact the availability of essential components or materials.

Define and track key performance indicators (KPIs):

Establish and monitor key performance indicators (KPIs) relevant to procurement and supply chain operations. Routinely evaluate these metrics and adapt strategies accordingly. By defining measurable indicators, organizations gain insights into the effectiveness of their procurement and supply chain processes. Regular reviews enable timely identification of areas for improvement and the ability to make informed adjustments. This data-driven approach enhances operational efficiency, supports informed decision-making, and ensures alignment with organizational goals. Tracking KPIs becomes a dynamic tool for continuous improvement, fostering agility and responsiveness in adapting procurement and supply chain strategies to evolving business demands and market conditions.

Continuous Improvement:

It’s important to always evaluate and enhance your procurement and supply chain procedures. This can be done by regularly reviewing and adjusting your strategies based on past experiences. By integrating these strategies, mid-sized businesses can increase their ability to adapt and respond quickly in procurement and supply chain management. This adaptability is crucial in adjusting to market changes, reducing risks, and staying competitive in today’s business environment.

Contact us now to solve your procurement problems!

Author’s Details

Manpreet Kaur

Assistant Manager Presales – Sourcing and Procurement Intelligence

Manpreet is a presales specialist at Infiniti Research and has expertise in sales, business strategy execution, and innovative solution design. She is actively involved in supporting clients from F&B, CPG, Healthcare, Pharma, Chemicals, BFSI, Oil & Gas and Automotive sectors.