By: George Mathew

Supply chain risks are a major concern for manufacturing companies due to their global and interconnected nature. Disruptions can stem from various sources including geopolitical tensions, natural disasters, economic fluctuations, and unforeseen events such as pandemics and cyber threats. These possible disruptions or uncertainties can lead to production delays, higher costs, and ultimately lead to lost revenue. A proactive and comprehensive supply chain risk management strategy plays a crucial role in mitigating these risks and ensuring a resilient and continuity in the supply chain.

With the continuously evolving market dynamics, companies face several challenges in implementing effective strategic sourcing solutions and mitigating supply chain risks. These risks include supplier alignment with quality and delivery needs, effective relationship management, diversity considerations, regulatory compliance, digital data management, sustainability practices, stakeholder alignment, and market agility. According to the Business Continuity Report (BCI) Supply Chain Resilience Report 2023, nearly one-thirds of disruptions observed in 2022 stemmed from Tier 2 suppliers and lower tiers.

Implementing a supply chain risk management solution in manufacturing operations offers significant benefits. To safeguard supply chains, companies should prioritize these top 10 supply chain risk mitigation strategies including enhancing resilience against disruptions, improved visibility across the supply chain, conducting regular risk assessments, optimization of inventory levels, building resilient logistics networks, prioritizing data security to mitigate cyber threats, developing business continuity plans, managing supplier risks effectively, foster collaboration across the supply chain ecosystem. and long-term sustainability through stronger supplier relationships and network. This approach involves negotiating better pricing, optimizing inventory levels, and fostering efficient processes to minimize risks and enhance supply chain efficiency, ensuring robust operational continuity and adaptability in a dynamic market landscape.

Categorization of strategies for mitigating supply chain risks:

Proactive risk management

Building a robust and efficient supply chain is crucial for any manufacturing operation. However, unforeseen disruptions can cause significant challenges. Proactive risk management, coupled with strategic sourcing solutions, is the key to mitigating these business information risks and creating a sustainable competitive advantage. Proactive risk management in supply chains mitigates disruptions by assessing and managing risks through supplier assessments, data analysis, and scenario planning. By identifying vulnerabilities and developing contingency plans, companies ensure supply chain resilience. Enhancing efficiency, reducing costs, and maintaining quality through process optimization and innovation creates value. Strong supplier relationships, built on trust and open communication, further reduce risks. Strategies such as diverse supplier network, risk diversification, and stringent quality assurance minimize delays. Strategic sourcing, considering total cost of ownership and sustainability, ensures a robust supply chain. This comprehensive approach enhances supply chain performance and competitiveness.

Reactive or real-time risk management

Traditional supply chains often suffer from reactive risk management, leading to delays and dissatisfied customers. In contrast, real-time risk management takes a proactive stance by leveraging technology to identify potential risks before they impact operations. This approach involves contingency planning, alternative sourcing strategies, and maintaining backup inventory. Technologies such as predictive analytics, IoT sensors and implementing import management software play crucial roles in detecting risks and ensuring supply chain visibility. By integrating real-time risk management with strategic sourcing solutions, businesses can build a resilient and efficient supply chain, enhancing customer satisfaction and mitigating disruptions.

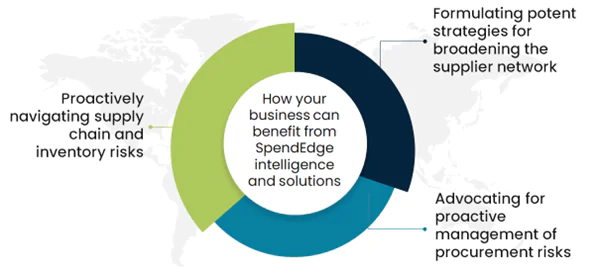

How SpendEdge can help businesses in building efficient supply chain risk management strategies:

Formulating potent strategies for broadening the supplier network

Our sourcing advisors are crucial in streamlining processes, integrating optimal methods, and reducing inefficiencies. By conducting thorough market analyses, they craft efficient strategic sourcing plans to mitigate risks and enhance resilience during challenging periods. Providing valuable perspectives, they pinpoint a wide range of suppliers from key sourcing regions. They meticulously assess variables such as risk probability, cost, logistic risks, quality, labor accessibility, and proximity, enabling companies to make well-informed choices and adopt budget-friendly procurement approaches.

Advocating for proactive management of procurement risks

Our advisors assist clients and senior management in recognizing and addressing various business information risks. These include financial, operational, supply chain interruptions, regulatory challenges, geopolitical factors, and demand volatility. Our specialists also offer guidance in understanding potential consequences and making informed decisions regarding security and legal adherence, protecting sensitive information and averting legal issues.

Proactively navigating supply chain and inventory risks

Our experienced advisors reassess the risks and benefits of stockpiling in the company’s supply chain, define clear objectives, conduct comprehensive risk analysis experiment, and explore optimization strategies, including scenario planning. They assist in implementing chosen strategies, communicating changes to stakeholders, and continuously monitor and adapt to evolving market conditions, enhancing supply chain resilience while optimizing operations. Additionally, our procurement advisors offer expert guidance and recommendations, helping senior management stay informed about supply chain advancements, monitor supplier capabilities, disruptions, regulatory shifts, and global market changes, and devise strategies to mitigate associated risks.

Success Story: How we helped a prominent pharmaceutical company in mitigating supply chain disruptions:

Our client is a US-based leading pharmaceutical company with a global presence, specializing in the development and manufacturing of innovative medicines.

Our client faced a challenge as they depended entirely on a single source for a key raw material, leaving them vulnerable to disruptions and fluctuations in prices. Additionally, increasing expenses and ineffective inventory control added to the risk of impacting their financial performance.

Our experts at SpendEdge conducted a comprehensive supply chain analysis, identifying vulnerabilities and collaborating to develop a strategic sourcing roadmap aligned with business goals. Diversifying the supplier base and negotiating favorable contracts mitigated risks, while robust monitoring ensured compliance. Lean inventory management and technology solutions optimized operations, enhancing agility and continuity during emergencies.

Our solutions enabled the client to significantly mitigate the disruption risks, ensuring continuous critical material supply, lowering costs, and enhancing operational continuity in the pharmaceutical market.

Contact us now to solve your procurement problems!

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.