By: George Mathew

Key takeaways for procurement in logistics

- Efficient transportation procurement involves selecting the most suitable method for specific purposes, such as relocating staff or delivering products, to reduce costs and ensure job suitability.

- Procurement teams in logistics face challenges in balancing cost efficiency and quality, navigating complex transportation networks, and ensuring timely deliveries while maintaining visibility in shipping operations.

- The procurement life cycle involves identifying requirements, assessing suppliers, negotiating contracts, completing purchase orders, processing payments, auditing deliveries, and maintaining invoices for future audits.

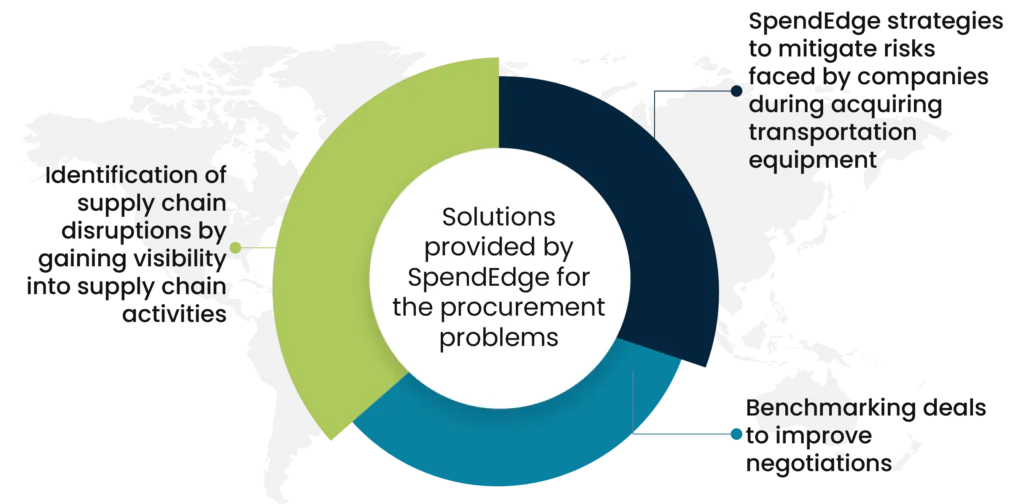

- SpendEdge provides solutions for identifying supply chain disruptions, benchmarking deals to improve negotiations, and mitigating risks faced by companies during the acquisition of transportation equipment.

Today’s transportation landscape is more complex than ever before. It’s no longer just about pricing, it’s about the entire freight-sourcing process. This raises the question: How do shipping companies create strategic supplier sourcing strategies that ensure they’re getting the capacity they need at a fair price to both sides?

Choosing the most suitable transportation method for a specific purpose is known as transportation procurement. This purpose can be anything from relocating staff to delivering products. It may also involve acquiring new or used vehicles, equipment purchases, or contracting for services such as airline travel or port management. Transportation procurement is crucial as it can reduce transportation costs while also ensuring that the selected mode of transportation is suitable for the job. The strategic management of transportation logistics can streamline supply chain operations and enhance overall efficiency for businesses across various industries.

Challenges faced by the procurement team in logistics while sourcing transportation equipment

Balancing cost efficiency and quality in transportation procurement:

Managing costs is a crucial aspect of transportation procurement, achieving a balance between cost-effectiveness and service excellence is essential, but it can be difficult. Having expertise in supply chain management is necessary to secure favorable rates with carriers while maintaining high standards. The procurement teams must search for and implement ways to optimize their costs while not compromising the quality. They should identify suppliers who can provide standard quality products at competitive prices. The complexity of transportation equipment also makes it difficult to procure as the process used for its manufacturing is complex, making it more expensive.

Unravel the complex landscape of transportation providers:

Navigating through a labyrinthine transportation network proves to be a daunting task given the plethora of options given. Managing such a vast transportation network becomes complex due to the multitude of carriers and transport modes, including road, rail, water, air, and pipeline for fuels or other liquids. Conducting comprehensive research and analysis becomes imperative to work out the optimal fit among these options tailored to your specific needs, enabling well-informed decisions. For example, when it comes to transporting consumer goods, rail transport emerges as the most cost-effective solution, while opting for waterways becomes advantageous when freight costs for shipment are lower.

Ensuring timely deliveries and visibility in shipping operations:

One of the paramount challenges lies in ensuring punctual deliveries and transparency throughout the shipping process. Any delays or disruptions in transportation can have detrimental effects on businesses, resulting in customer dissatisfaction and financial setbacks. Therefore, implementing robust tracking systems and fostering clear communication channels with carriers becomes imperative to mitigate such risks. Procurement and logistics management teams play a pivotal role in fortifying their supplier base to uphold a seamless flow of materials. They must establish resilient supplier networks comprising dependable and trustworthy suppliers, prioritizing not only timely deliveries but also maintaining premium or standard quality of products.

Seven crucial steps in the procurement life cycle

1. Identify requirements

The process of procurement begins with the requirement to acquire goods or services from an external company. These goods or services can either be for internal purposes such as materials needed to run the business or for external purposes such as raw materials or finished products that the business will eventually sell. This stage involves assessing the needs of each department and setting an appropriate budget accordingly.

2. Identifying and assessing supplier information

This stage involves finding suppliers and assessing their ability to provide the best quality and value for goods or services. It’s important to identify reputable vendors with whom you can build a long-term partnership. Strategic procurement, the best practice in this area, focuses on aligning procurement strategy with broader business objectives rather than treating it as an afterthought. In other words, strategic procurement is proactive and deliberate, rather than reactive. When evaluating vendors, it’s important to thoroughly compare all available options. Ideally, reputable suppliers exhibit accountability, production capacity, strong ethics, and open communication.

3. Selecting the best suppliers and deciding on negotiation contracts

Once you have selected your preferred potential suppliers, the next step in the procurement process is to negotiate the contract terms with them. This is a very important step as it allows both parties to reach a fair price and to incorporate any additional payment term features such as supply chain finance or dynamic discounting. Before entering negotiations, you should analyze your previous contracts to identify opportunities that could help you streamline costs and save money.

4. Completing purchase order

After a contract has been submitted to a supplier and both parties have agreed to the terms, the next step is to begin preparing, finalizing, and sending purchase orders or purchase requests. A purchase order is a document that includes a description of the goods or services, total costs, quantity, and approval of workflow. Once a purchase order is approved, it informs the relevant finance team to release the details to the supplier, providing them with necessary information such as a reference number, payment terms agreement, and any other essential details. Purchase orders are typically sent via email and serve as a further agreement between the two parties. While a contract outlines the agreements for the entire collaboration, purchase orders specifically agree to individual jobs contractually.

5. Process payment and collect invoice

After a supplier receives a purchase order, the sender of the purchase order will receive an invoice from them, which includes the agreed price and instructions on how to pay. The invoice should contain details of the order. It’s crucial to streamline your purchase order management process to optimize this aspect of the procurement process. One way to achieve this is to adopt invoice automation technology. Depending on the contract, the invoice will specify the payment period. Most businesses offer a thirty-day credit notice, giving you time to make the payment if you can’t pay at the time of the order. However, payment terms are specific to the contractual agreement and the relationship between both parties.

6. Auditing and deliveries

All things going well, the delivery of ordered goods should arrive soon after the supplier receives a purchase order. At this stage of the process, it’s common for businesses to make a record of when the order arrived as well as double-check the order contents. If something is missing, this is the opportunity to contact the supplier and rectify the problem to reduce potential downtime.

7. Maintaining appropriate and required invoices for future audits

It’s an essential part of the process to keep up-to-date records of all invoices and payments. Then, when it’s time for a cash flow audit, you can precisely calculate what you’ve spent throughout the contract and identify areas where you can further analyze your spending. Maintaining accurate invoices is also key to working out whether you’re overspending or sticking to your budget.

Solutions provided by SpendEdge for the procurement problems while sourcing transportation equipment

Identification of supply chain disruptions by gaining visibility into supply chain activities:

Our procurement and sourcing consulting specialists understand the complexity of supply chain management. They can conduct thorough assessments to identify inefficiencies and bottlenecks of the supply chain and identify areas where cost savings can be realized. This involves optimizing routes, consolidating shipments, and recommending changes to transportation modes where appropriate. We provide advance alerts on supply-side performance efficiency and unplanned events that could potentially upend your delivery chain and cause you financial and reputational loss. With the aid of our supply-side intelligence, companies can fashion a lean and cost-effective supply chain.

Benchmarking deals to improve negotiations:

SpendEdge have access to benchmarking data and industry standards. We use this information to negotiate favorable terms and rates with transportation providers. By leveraging our market knowledge, the company can secure competitive pricing while maintaining service quality. Companies may discover, examine, and create complete plans with the help of the deal benchmarking that we are providing. Additionally, they can pinpoint crucial demands and specifications, the finest industry norm for agreements and contracts, and the top suppliers and vendors to work with. Businesses can analyze their competitors’ strategies and technology, along with industry leaders, as part of deal benchmarking. This analysis helps chief product officers CPO and supply chain managers make research-driven decisions and strategies.

SpendEdge strategies to mitigate risks faced by companies during acquiring transportation equipment:

SpendEdge develops comprehensive risk mitigation strategies that anticipate potential transportation challenges including creating contingency plans to minimize the impact of delays or disruptions on businesses. Get unified enterprise-wide views of risk to initiate effective remediation and quantify the potential impact of critical vulnerabilities on business operations. Identify fresh possibilities to improve supply chain resiliency and capacity for recovery and make compelling arguments for increasing supply chain investment. Have a backup strategy that includes a number of providers in various areas. Gather quantitative data on supplier experience of delivering transportation equipment to refine the supply chain and determine fair prices for the equipment with the help of cost/pricing data.

The Procurement in Logistics Success Story: How SpendEdge Transformed a Multinational Transportation Company

Transportation vehicles are intricate pieces of equipment that require thorough analysis and strict supervision during production to ensure safety. It’s crucial that they are in good working conditions and safe to use. To achieve this, a reliable procurement function is necessary to acquire the best equipment.

A multinational logistics and transportation company headquartered in the US with a vast fleet of vehicles, including trucks, trailers, and specialized transport equipment sought the expertise of SpendEdge as they were facing challenges in procuring and managing their extensive transportation equipment fleet efficiently. Key issues included rising operational costs, suboptimal equipment utilization, and difficulties in maintaining and renewing their fleet due to varying market conditions and supplier relationships. They sought a strategic procurement solution to optimize their equipment acquisition and management processes.

After complete and extensive market research and analysis, the experts at Spendedge identified potential suppliers, equipment manufacturers, and leasing options. This research involved evaluating the reputation, reliability, and financial stability of prospective suppliers. The client’s transportation equipment procurement process became more efficient and cost-effective. They experienced a 15% reduction in equipment acquisition costs, a 20% improvement in fleet utilization, and a 30% increase in supplier reliability.

Conclusion

To conclude, effective procurement and logistics management play a significant role in optimizing a company’s resources and stock management. By strategically navigating the procurement cycle and procurement process, businesses can ensure a seamless flow of procurement logistics within their supply chain. Collaborating with a determined procurement logistics team empowers companies to maintain adequate safety stock levels, streamline purchasing activities, and enhance overall supply chain efficiency. With meticulous attention to inventory management and supplier relationships, companies can mitigate risks, minimize costs, and maximize the value derived from their procurement operations. As a result, the successful flow of procurement logistics is integral to the sustained success of any company operating within the complex landscape of modern logistics.

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.