By: George Mathew

Key takeaways

- Supplier Selection is vital for establishing reliable and efficient supply chain operations, impacting product quality and overall business performance.

- Evaluating vendor criteria like Supplier Quality, Delivery, and Quality of Service strengthens organization operations and enhances long-term partnerships.

- Regular Supplier Audits and effective negotiation and contract management ensure compliance and mutually beneficial agreements, minimizing risks.

- A strategic approach to supplier selection improves business performance, optimizes costs, and provides a competitive advantage.

What is supplier selection?

The process of deciding which potential vendor or supplier an organisation should do business with is known as supplier selection. Establishing a profitable business-to-business partnership with a dependable supplier that offers the best value for money is one of the main objectives of the supplier selection process.

What is the Importance of Supplier Selection?

Supplier selection and evaluation are critical in business for ensuring the supply chain’s reliability, quality, and efficiency. Choosing the right suppliers impacts product/service quality, cost, and overall business performance.

Choosing the right suppliers helps mitigate risks, enhance competitiveness, and maintain customer satisfaction. Effective Supplier Selection and evaluation contribute to long-term partnerships, streamlined operations, and adaptability to market changes, thereby fostering a resilient and successful business ecosystem.

Moreover, developing a set of criteria to evaluate your vendor can directly benefit your organization by strengthening your position in negotiations. A supplier who performs well in most areas but struggles in one particular area may be willing to offer better pricing or terms to secure your business. You can then use these savings to create a contingency plan in your supply chain to address the supplier’s weakness, which will eliminate any excessive risk and ultimately lead to increased profits and a competitive advantage.

Focusing on Supplier Quality ensures that the goods and services you receive meet your standards, enhancing the Quality of Service you provide to your customers. Regular Supplier Audits can help monitor performance and compliance with contract terms, ensuring consistent and reliable delivery. By maintaining strong relationships with your suppliers, you can create a more adaptable and efficient supply chain that supports your long-term business goals.

Supplier selection and evaluation process

Identifying exact requirements such as type of raw materials

Identifying exact requirements involves a meticulous analysis of the specific needs, particularly regarding raw materials. This step entails a detailed examination of the raw materials essential for production, considering factors like quality standards, quantity, and technical specifications. Understanding these requirements is crucial for aligning procurement processes with production goals, ensuring optimal performance, cost efficiency, and the ability to meet quality standards. By precisely identifying raw material needs, businesses can enhance resource planning, minimize waste, and maintain consistent product quality.

Supplier evaluation: Capability, financial status, location, price, and flexibility

Supplier evaluation encompasses assessing various factors for effective decision-making. Evaluating supplier capability ensures they meet quality and quantity requirements. Examining financial status ensures stability and reliability. Location impacts logistics and delivery times. Pricing considerations affect overall cost-effectiveness. Lastly, flexibility is crucial for adapting to changes in demand or unforeseen challenges. This comprehensive evaluation process ensures the selection of suppliers aligning with business goals, promoting sustainability, and minimizing risks in the supply chain, fostering long-term, mutually beneficial relationships.

RFx processes to narrow down your list

The RFx (Request for X) processes, including RFQ (Request for Quotation), RFI (Request for Information), and RFP (Request for Proposal), play a pivotal role in supplier selection. By issuing these requests, businesses gather detailed information on supplier capabilities, pricing, and terms. Analyzing the responses helps narrow down the list of potential suppliers based on factors like competitiveness, alignment with requirements, and overall suitability. This systematic approach streamlines the selection process, ensuring that chosen suppliers meet specific criteria, promoting efficiency, and informed decision-making.

Supplier selection: choosing the right fit supplier, pricing, and contract negotiation

Supplier selection involves choosing the most suitable supplier based on various criteria, including capability, reliability, and alignment with business needs. Pricing negotiations ensure cost-effectiveness and competitiveness. Contract negotiation establishes terms, conditions, and expectations, fostering a clear understanding between both parties. Choosing the right fit supplier, considering quality and value for money, enhances overall operational efficiency and product/service quality. This step is crucial for establishing successful, mutually beneficial partnerships, minimizing risks, and achieving long-term business objectives.

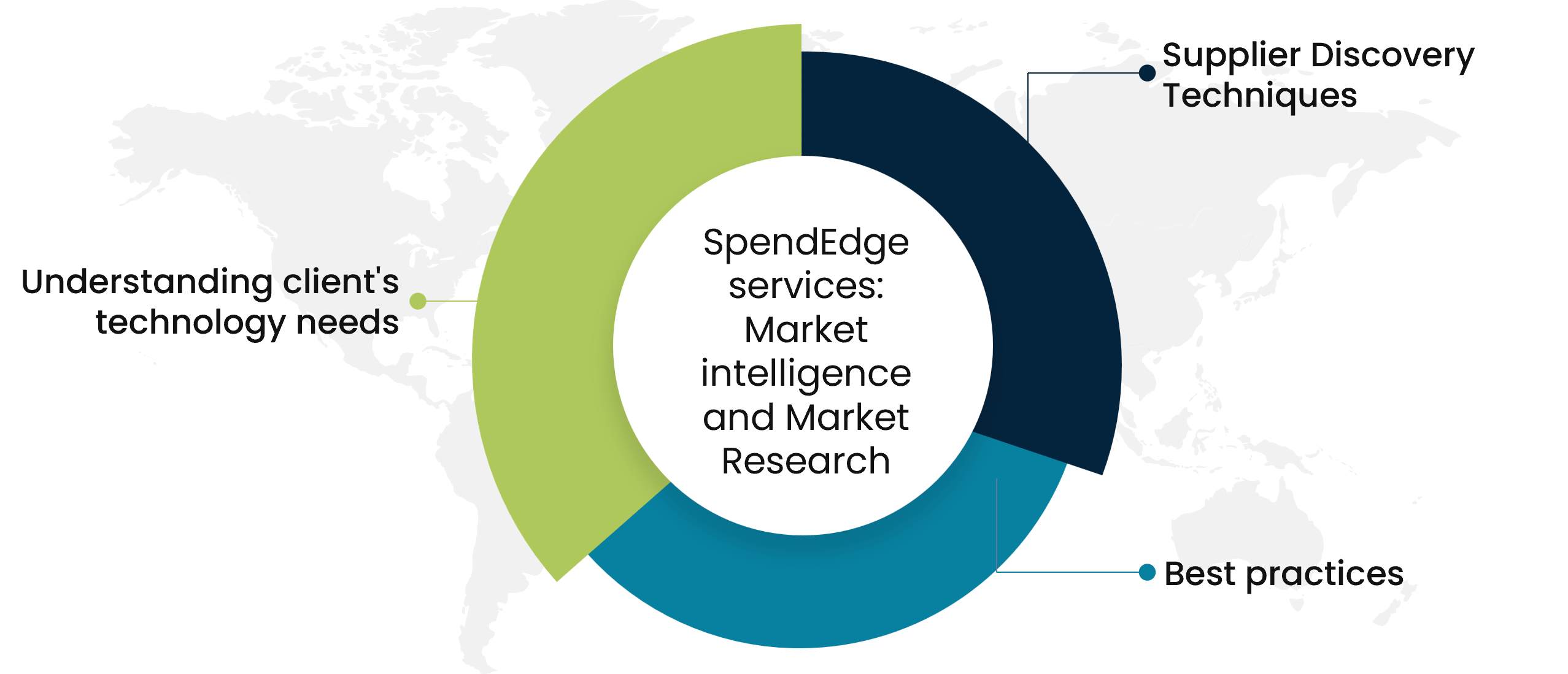

How SpendEdge can help companies in smart supplier selection

Identifying and evaluating supplier capabilities with market research

At SpendEdge, we assist you in narrowing down the potential supplier base by defining business outcomes clearly. We help you sift through a pool of suppliers to effectively understand the available options and streamline your search to include only those suppliers that can meet all or most of your requirements. We help you identify criteria that are crucial to achieving supplier engagement objectives and gauge supplier capabilities based on these criteria. We also provide detailed information about supplier performance specific to each KPI. We sort suppliers into quadrants based on operational and functional capabilities and rank them to identify the best-fit suppliers. We help you gain additional information about the most suitable suppliers for engagement.

Sourcing solutions: risk management and compliance

SpendEdge offers comprehensive risk management and compliance services to support businesses in their sourcing processes. This involves sourcing solutions that encompass legal, regulatory, technical, and contractual aspects. Our expertise helps companies in navigating complex legal and regulatory landscapes, ensuring that sourcing activities comply with relevant standards. We also offer technical support to address specific industry requirements. Additionally, our services include the development and implementation of robust risk mitigation strategies, safeguarding clients from potential disruptions, and enhancing overall supply chain resilience.

Cost management and contract negotiation

SpendEdge excels in cost management and contract negotiation by negotiating favorable terms with suppliers on behalf of businesses. This includes skillful negotiation of rates, payment terms, and other contractual elements. We go beyond traditional negotiations, actively identifying and capitalizing on cost-saving opportunities within the supply chain. By leveraging our market intelligence and industry expertise, SpendEdge helps clients secure advantageous contracts, optimize procurement costs, and enhance overall financial performance. This service plays a pivotal role in achieving cost efficiency, improving the bottom line, and ensuring that clients receive optimal value from their supplier relationships.

The success story of SpendEdge helping one of its clients optimize supplier relationships

Our client is a US-based CPG company with operations carried out around the globe and was keen on optimizing its supplier relationships to enhance efficiency, reduce costs, and improve overall supply chain resilience.

Our team of experts at SpendEdge has conducted thorough market research to identify potential suppliers in the CPG industry. We have used data-driven methodologies to shortlist suppliers based on their performance, reliability, and industry reputation. Our evaluation framework is comprehensive and takes into account factors such as quality, scalability, sustainability, and financial stability. Furthermore, we have conducted on-site visits and interviews to assess the capabilities of the suppliers. Based on our analysis, we have presented our client with a concise list of recommended suppliers. We have also worked closely with our client to establish negotiation objectives and have engaged in discussions with the shortlisted suppliers to secure favorable terms, which include pricing, payment terms, and delivery schedules.

Our solutions helped the client to make strategic supplier decisions, enhancing their competitiveness in the dynamic CPG industry. The smart supplier selection approach not only optimized costs but also fortified their supply chain against uncertainties.

Contact us now to solve your procurement problems!

Conclusion

Supplier Selection is a critical process for any organization aiming to establish reliable and efficient supply chain operations. By carefully evaluating potential vendors based on criteria such as Supplier Quality, Delivery, and Quality of Service, businesses can secure the best value and build strong, long-term partnerships. Regular Supplier Audits ensure compliance and maintain high standards, while effective negotiation and contract management foster mutually beneficial agreements. Ultimately, a well-executed supplier selection strategy enhances overall business performance, mitigates risks, and drives competitive advantage.

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.