Key Takeaways

- Integral Role of Packaging: Packaging is crucial in supply chain management, impacting order processing, production, procurement, and distribution by ensuring product safety, integrity, and efficient delivery in both B2B and B2C transactions.

- Optimization and Sustainability: Effective packaging optimization involves right-sizing, using lightweight and durable materials, and integrating sustainable practices to reduce waste, shipping costs, and environmental impact.

- Technological Integration: Advanced packaging solutions, such as smart packaging and RFID technology, enhance tracking and logistics, improving visibility and minimizing errors throughout the supply chain.

- Strategic Asset: Recognizing packaging as a strategic asset allows companies to streamline manufacturing and production, enhance quality control, and improve order management and sales order processing, leading to cost savings and sustainable growth.

In the fast-paced world of modern business, the success of a company hinges not only on the quality of its products but also on its ability to efficiently manage its supply chain. At the heart of this intricate process lies a crucial element often overlooked: packaging. Today, we delve into the multifaceted world of packaging in supply chain management, exploring its pivotal role and undeniable importance.

What is supply chain management?

Supply chain management is the process of facilitating the movement of goods and services. This includes taking raw materials or goods and turning them into finished products. Supply chain activities encompass product development, sourcing, manufacturing, logistics, and tracking.

Understanding the Functions of Packaging

Packaging serves as much more than a mere container for products; it plays a multifunctional role throughout the supply chain. From protecting goods during transportation to conveying vital information to consumers, the functions of packaging are diverse and indispensable.

First and foremost, packaging ensures the safety and integrity of products, safeguarding them from damage, spoilage, or contamination throughout the distribution process. Additionally, it serves as a vehicle for branding and marketing, conveying a company’s identity and communicating essential product information to consumers.

Supply Chain Management Flow

Procurement

The initial stage entails the sourcing and acquisition of raw materials necessary for packaging creation from vendors. Implementing flowcharts to streamline the procurement workflow serves to minimize redundant supplier research.

Material Management

Material management encompasses the process of ensuring the availability and adequacy of essential components for use during manufacturing and production.

Manufacturing and Production

This phase involves the allocation of production orders and scheduling of manufacturing execution in specific sequences and time frames within the supply chain. A meticulously planned flow chart for this phase can reduce lead times.

Order Management

This stage encompasses the aggregation, validation, and documentation of all pertinent information required for the fulfillment and processing of customer orders. Effective and efficient customer data management serves to minimize order errors, expedite the distribution process, and enhance customer satisfaction.

Distribution

The distribution process entails the coordination of orders, inventory and warehouse management, and the delivery of products or goods to customers. An optimized distribution process can reduce order errors and enhance inventory location accuracy.

The Packaging Process in Supply Chain Management

Effective supply chain management entails meticulous attention to every step of the packaging process. From design and manufacturing to distribution and disposal, each phase plays a critical role in ensuring seamless operations and customer satisfaction.

In manufacturing, the packaging process involves not only selecting the appropriate materials but also optimizing packaging designs for efficiency and sustainability. By implementing lean practices and incorporating eco-friendly materials, companies can streamline their packaging operations while reducing environmental impact.

Packaging Optimization in the Supply Chain

Packaging optimization lies at the core of efficient supply chain management. By fine-tuning packaging designs and materials, companies can minimize waste, reduce shipping costs, and enhance overall sustainability.

One key aspect of packaging optimization is right-sizing—tailoring packaging dimensions to match product specifications, thereby maximizing space utilization and minimizing excess material. Additionally, lightweight and durable materials can reduce transportation costs and environmental footprint without compromising product protection.

The Packaging Value Chain

In the intricate web of the supply chain, packaging serves as a vital link connecting manufacturers, distributors, retailers, and consumers. The packaging value chain encompasses a series of interconnected processes, from raw material sourcing to end-of-life disposal, each contributing to the overall efficiency and effectiveness of the supply chain.

Moreover, packaging optimization extends beyond the physical realm to encompass digital solutions such as smart packaging and RFID technology. These innovative approaches enable real-time tracking and monitoring of products throughout the supply chain, enhancing visibility, and traceability while minimizing errors and losses.

The Critical Role of Packaging in Supply Chain Management

In today’s hyper-competitive marketplace, the importance of packaging in supply chain management cannot be overstated. Effective packaging not only ensures product safety and integrity but also enhances brand reputation, customer satisfaction, and ultimately, profitability.

By recognizing packaging as a strategic asset rather than a logistical afterthought, companies can unlock a wealth of opportunities for efficiency gains, cost savings, and sustainable growth. Proactive packaging management is essential for staying ahead in an ever-evolving business landscape.

Effective packaging plays a pivotal role in various aspects of supply chain management, including order processing, production, procurement, and distribution. It impacts both B2B and B2C transactions by ensuring that products reach their destination in optimal condition.

In product development, thoughtful packaging design can significantly influence customer perceptions and purchasing decisions. Additionally, during sourcing and manufacturing, selecting the right packaging materials and designs can streamline the procurement workflow and reduce the need for duplicate supplier research.

Packaging is integral to manufacturing and production processes, affecting production planning, scheduling, and quality control. Efficient packaging solutions can enhance order management and sales order processing, ensuring timely delivery and customer satisfaction.

Moreover, in the realms of logistics and tracking, well-designed packaging facilitates easier handling and accurate monitoring throughout the supply chain. By integrating advanced technologies, companies can improve purchase order processing and maintain better control over their procurement and distribution networks.

Ultimately, recognizing the strategic importance of packaging within the supply chain framework allows companies to optimize their operations, reduce costs, and achieve sustainable growth. This holistic approach to packaging ensures that every aspect, from production to distribution, is aligned with the company’s overall business objectives.

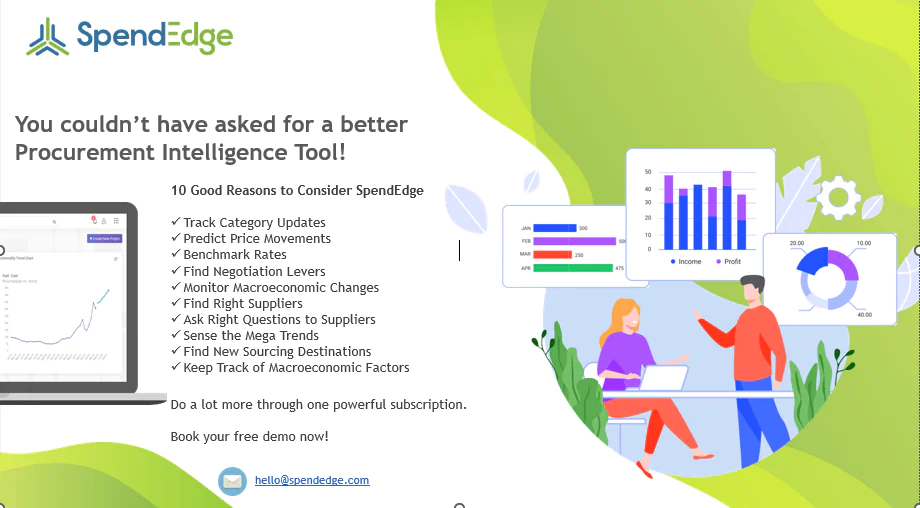

Why choose SpendEdge?

Conclusion

Packaging plays a central role in the complex ecosystem of supply chain management. From protecting products to promoting brand identity and sustainability, the functions of packaging are diverse and far-reaching. By prioritizing packaging optimization and embracing innovative solutions, companies can enhance efficiency, reduce costs, and drive long-term success in today’s competitive marketplace. As leaders in the industry, it is imperative to recognize the critical role of packaging and leverage it as a strategic asset in supply chain management.